High quality EPS flame retardant coating machine fluidized bed dryer

i) Joint R&D with the authoritative research bureau of China. According to our independent developed fire retardant technology parameter (such as components, characters, viscosity, soften temperature, thickness of coating, eps borad density) to design and fix, in order to improve the productivity and production quality.

ii) Equipped with automatic weighting and pressure painting system, to keep the material matching automatic and accurate, and guarantee producing continuous.

iii) Air separation system to separate and scatter the small joint block of material to keep the granules coating proper and stable, and achieve the finish production at high ratio.

iv) Micro-pressurized status to reduce the smell come out.

v) PLC (Programmable Logic Controller) and Color Touch Screen operation system.

vi) Equipped our independent developed specialized feeding blower, prevent the granules go through the blade wheel then drop out directly, and avoid the powder removal, to ensure the production fire retardance and workable.

Parameter:

| No | Item | Unit/Type | Parameter |

| 1 | Steam pressure | Mpa | 0.3~0.5Mpa |

| 2 | Air-Compressed pressure | Mpa | 0.6Mpa |

| 3 | Effective volume | m3 | 4 |

| 4 | Production capacity | m3/h | 24 |

| 5 | Installed power | KW | 140 |

| 6 | Max contour size | mm | 18000x8.6x7.5 |

| 7 | Machine Weight | T | 20 |

Patent and application:

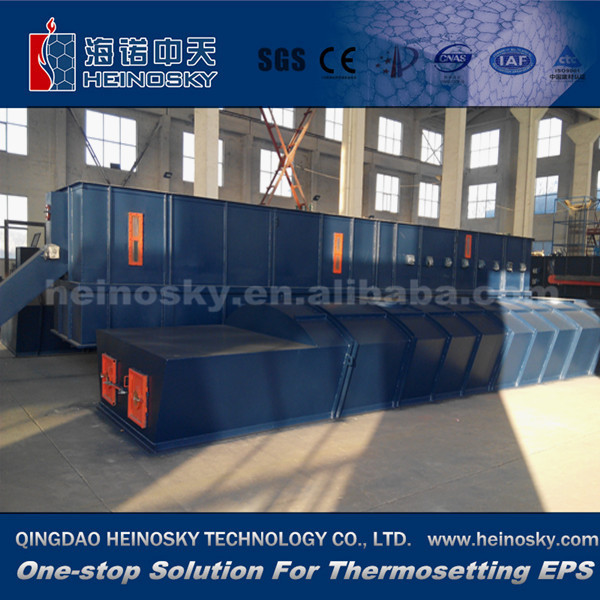

Factory View:

Why Choose us?

1. We have introduced South Korea and Taiwan technology with more than 30 years experience. Our machine quality is the best.

2. Our salesman will be 24 hours online for you to solve problems.

3. After sales service: we will dispatch professional technicians to customer factory for machine installation and training.

How to contact us?

Tel:+86